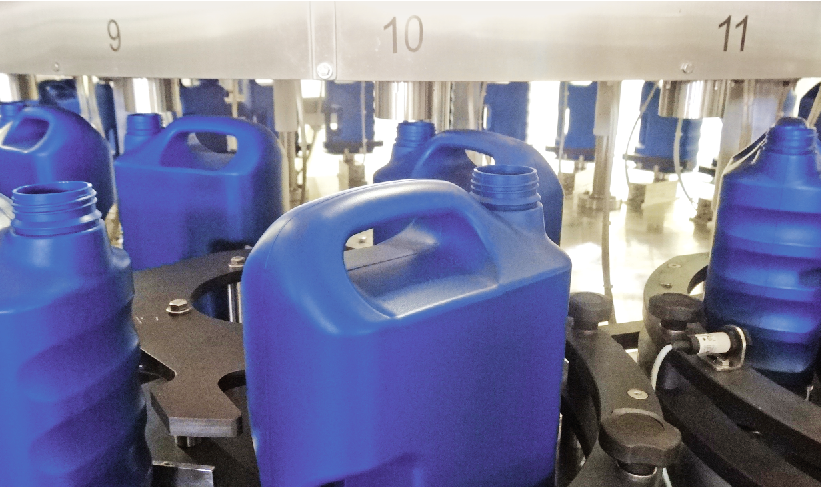

Bottling for Oil/Lubricant

WEIGHING FILLER

Our weighing filler is suitable for filling non-carbonated product especially for any kinds of oil and milk into cans and bottles.

HIGH ACCURACY

Once the containers are transferred to filler, the empty weight of each individual container will be determined. The system will then start filling from zero to ensure the exact product filling volume.

EASY OPERATION

Two filling speeds (Mass Flow / Fine Flow) are available for adjusting flexibly to suit products of different character. All filling process steps for each filling head can be programmed on the touch panel individually and the exact filling volume will be showed on the screen.

BEST HYGIENE

For keeping the product from being contaminated, this system is completely covered with stainless steel. Also, to keep the neatness of the ground, this system is equipped with water colleting trough which collects and discharges the filling content or cleaning liquid into sewer.

INCREASE EFFICIENCY

Bottle rinsing, filling, and capping, three functions are connected perfectly. Our three in one bottling system minimizes the space needed and reduces energy consumption and pollution caused. Connecting the three units closer to each other also decrease the situation of bottle falling, which enable the system to perform stably under high speed production and further improves hygiene quality and manufacturing efficiency.

beverage bottling system / liquid bottling system